In 10 seconds? Although wind farms are iconic (and controversial) structures battling climate change by generating fossil-free energy, they have a dirty secret: their blades end up in landfills – which is not very eco-friendly. A recent paper reviewed the potential solutions… with some amusing results.

Why are we talking about this? Wind power is a low-cost, carbon-free technology that is increasing in popularity as the world takes steps to move away from fossil fuels and towards producing green energy. However, as wind turbines come to the end of their life, their huge blades must be decommissioned and many end up in a landfill. A recent review examined how we can reduce the waste produced from blades that have reached the end of their life.

And, what did they find? They proposed a recyclable polymer resin material to be used in turbine blade manufacturing. Why? This composite resin was found to be 100% recyclable… even into food-grade potassium lactate. One of the authors has even consumed the gummy bears that were partly made from the material proposed for the blades!

OK, so why are turbine blades causing such a headache? Wind turbines have an average lifespan of 20 to 25 years, following which they must be decommissioned and either removed or replaced. While the body of the turbine is made from steel and is easy to recycle, the blades are another story and in general, once they are decommissioned, they are sent to a landfill, rather than being recycled. This is because the structure of a turbine blade is complex and to reuse or recycle, it must be further processed which can often be time-consuming and costly. This has become more of a problem as wind turbine blade size has increased to allow them to produce more energy. In 2000, the average rotor diameter for a blade was 48 meters but by 2019 this had increased to 121 meters.

How much waste do they actually produce? Wind farms became more popular during the 1990s and early 2000s, which means that we are coming to a time when many will need to be dismantled and replaced. As a result, several studies have looked at the waste that will be produced year after year as wind turbine blades are decommissioned. For example, in Europe, it is predicted that by 2050 there will be 325,000 tonnes of waste produced from wind turbine blades every year and in the United States, the Electric Power Research Institute estimates that there will be 2.2 million tonnes of cumulative blade waste entering landfills over the next 30 years. While this sounds like a lot, it is just a fraction of the waste produced by other sectors. Plastic dishes, for example, contributed more to landfill in 2016 and 2017 than wind turbine blades are predicted to between now and 2050!

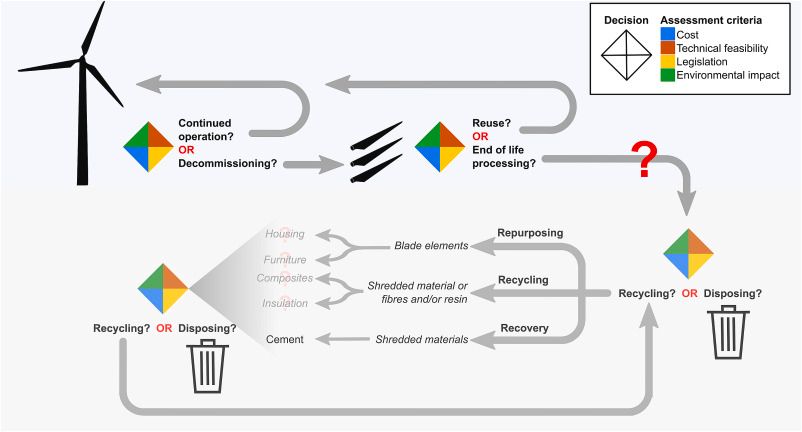

Ok, so what can be done to reduce this waste? There are several options for reusing or recycling wind turbine blades. This can involve using the whole blade as building materials for projects such as pedestrian walkways, land bridges over highways for wildlife, and for building play parks. The blades can also be broken down into smaller pieces and used for bridge parts, roof shingles, sea walls, and road signage to name a few. Some companies have even ground down the wind turbine blades into pellets or powders that can then be used to make other products. However, while this can be done, the cost is often a factor with companies preferring to use cheaper alternatives to recycled wind turbine blade parts.

Why do we need to recycle these parts anyway? There will be a lot of wind turbines coming to the end of their life cycle over the next few years and finding alternative solutions to a landfill for their blades is important to reduce waste. Some countries are also implementing bans on sending wind turbine blades to landfill (including Germany, Finland, Austria, and the Netherlands) and there are calls for an EU-wide ban to be in place by 2025. Finding alternative solutions for wind turbine blades also reduces the environmental impact that making wind turbines has which is important not only for the environment but also for increasing social acceptance of wind farms.

OK, but could we change the material of the turbine blade to make it easier to recycle? The answer is yes! As I mentioned above, researchers have recently discovered that the blades can be made from a new material that can easily be broken down and repurposed repeatedly, which is important for moving towards a circular economy and reducing waste. The thermoplastic resin has suitable physical properties for use in wind turbine blades so now it must be put to the test in the field, but if it works it could revolutionize wind turbine blade recycling and reduce the negative environmental impact disposal of these blades has.

Windfarms, are so modern, right? No, they aren't.

The truth is humans have been harnessing wind power for thousands of years.

The earliest windmills can be traced back to 2000 BC in countries like China and Iran, where they were used to lift water.

The world’s first electricity-generating wind turbine was built by James Blyth, a Scottish professor of engineering. He built a four-blade windmill using cloth sails.

Wind turbines these days are much more complicated than they look, they stand 80 – 90 meters tall and are made of over 8,000 parts!

Lindy has distilled 10 research papers saving you 35 hours of reading time.

The Science Integrity Check of this 3-min Science Digest was performed by Dr. ASM Mainul Hasan.