In 10 seconds? Researchers have developed a method to help break down high-density polyethylene (HDPE), one of the most widely produced commercial plastics in the world, which is notoriously difficult to recycle.

Why are we talking about this? Because of their limited recyclability, HDPE single-use plastics are littering the planet and filling up landfills worldwide. However, this could be about to change with the discovery of a new method, that could make this type of single-use plastic a thing of the past.

Great! So, what did they exactly discover and develop? Scientists at the US Department of Energy’s Argonne National Laboratory and Cornell University have developed a novel catalytic approach that converts our used HDPE single-use plastic items into a new material that is fully recyclable and potentially biodegradable. This new material also has the added bonus of retaining the mechanical and thermal properties of the original HDPE. This is particularly exciting, as HDPE is favored for its mechanical and thermal properties, which make it more robust than other materials.

OK, but we wanted to break down this plastic… what benefit could these properties have? HDPE is widely used in single-use plastics because it is cheap to produce and is suitable for use in a wide range of products due to the strength and flexibility of the material. However, the production of this plastic and the way we dispose of it is not only bad for the environment but can have long-lasting impacts on human health. Once disposed of, these plastics persist in the environment, and chemicals can leach from and contaminate the soil, lakes, rivers, and seas. And, they can break into micro or nano plastics endangering human and animal health all over the world. Components used in the manufacture of plastics can cause skin irritation, burns, and eye damage, and are also suspected of being carcinogenic. These plastics are also toxic to wildlife and have several negative impacts on the natural world, especially in the seas where chemicals leach into the water.

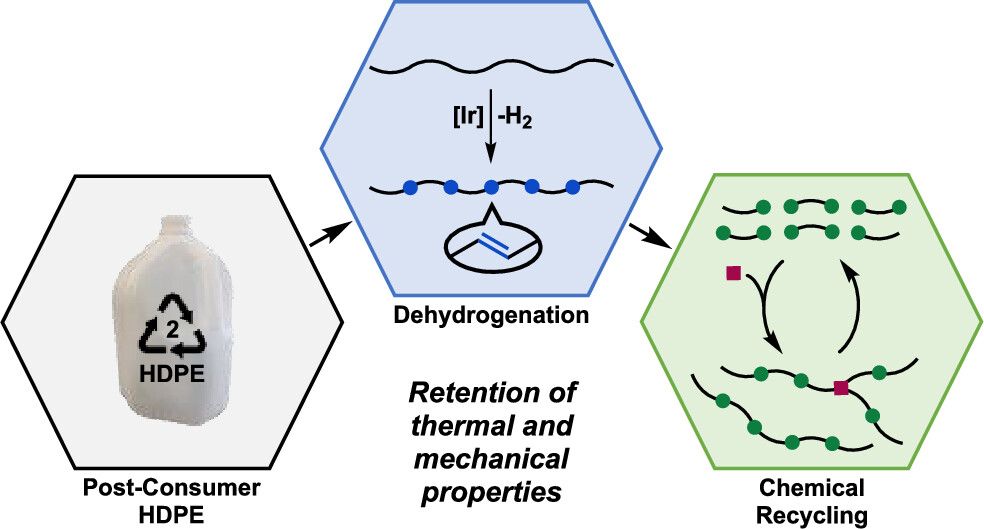

Ok, so how did the scientists find a way to recycle these plastics? The team used a chemical recycling route to convert HDPE into so-called “telechelic macromonomers” – low-molecular-weight polymers that have functional groups on either end. What is a functional group? It can be defined as an atom or a group of atoms that has similar chemical properties when it appears on any molecule. In this case, the functional groups are found at either end of the polymers.These telechelic macromonomers can then be recycled or left to decompose. The team’s technique differed from previous recycling approaches because the end product retained the same properties as the HDPE plastics.

How so? This new approach uses several different catalysts to carry out reactions that break down the polymers into smaller pieces. These pieces, which contain reactive groups at the ends, could then be put back together to produce a new product that is as durable as the starting material. It is these reactive end groups that are of particular importance because they make the plastic easier to decompose.

Great! So how can we expect this to be used? This new recycling technique could enable us to transform waste plastic into a new material that can be used over and over again without a loss in quality. This could not only reduce the amount of waste filling up our landfills or floating in our oceans but would also reduce the carbon emissions and pollution produced during plastic production. However, the reactions to transform this plastic also make use of various chemicals, such as toluene. So, if this was to be scaled up to deal with the vast amount of plastic waste produced worldwide, scientists would need to consider the chemicals used and how these would be safely disposed of without being toxic to the environment.

So, what’s next? To see if this method could be used commercially, the team will now need to focus on developing catalysts that can be used on a large enough scale worth investing in. The scientists will also test if this method can be applied to other types of widely used plastics with the same result. Lastly, the team will also need to further investigate if this plastic can be biodegraded and under what conditions this occurs. If this plastic is biodegradable, this method could help make the plastic industry more sustainable by phasing out plastic production and reusing plastics already in circulation.

Plastics and microplastics have become persistent pollutants in the environment…

Microplastics have been found in all the remote corners of the Earth, including the Mariana trench - the deepest oceanic trench on Earth at a whopping 11,000 meters deep.

Plastic has become such a problem that several floating garbage patches have developed in the world’s oceans. The largest of these is the Great Pacific Garbage Patch which covers an area of 1.6 million square kilometers – that’s twice the size of Texas!

Scientists estimate that by 2015 we had generated 6300 million tonnes of plastic waste and 79% of this ended up in landfills or the natural environment. Meanwhile, researchers have realized why plastic dumped in the seas “goes off the radar” i.e. is seen in smaller quantities than expected. Scientists have found a type of bacteria that digests the waste… but the news is not as good as it sounds: in the process, CO2 is released and larger bits of plastic are turned into microplastic.

Lindy has distilled 11 research papers saving you 38.5 hours of reading time.

The Science Integrity Check of this 3-min Science Digest was performed by Dr. ASM Mainul Hasan.