In 10 seconds? Environmental impacts and health concerns are turning more and more people against the use of plastics. Although the case against them is not black and white, several bio-based and degradable materials offer a viable consumer alternative.

What's the story? With news of patches of plastic floating in the oceans and tiny particles getting into the food chain, consumers are demanding change. Enter fiber-based renewable materials that can be used in packaging, construction, and even furniture manufacturing! Coincidence or not, the two largest CO2 emitters – i.e. China and the US – are the largest producers of wrapping, packaging paper, and paperboard, accounting for 49% of global production, according to data from 2013. And this was before the pandemic when increased growth of e-commerce and home deliveries nearly doubled the demand for carboard in 2021 alone.

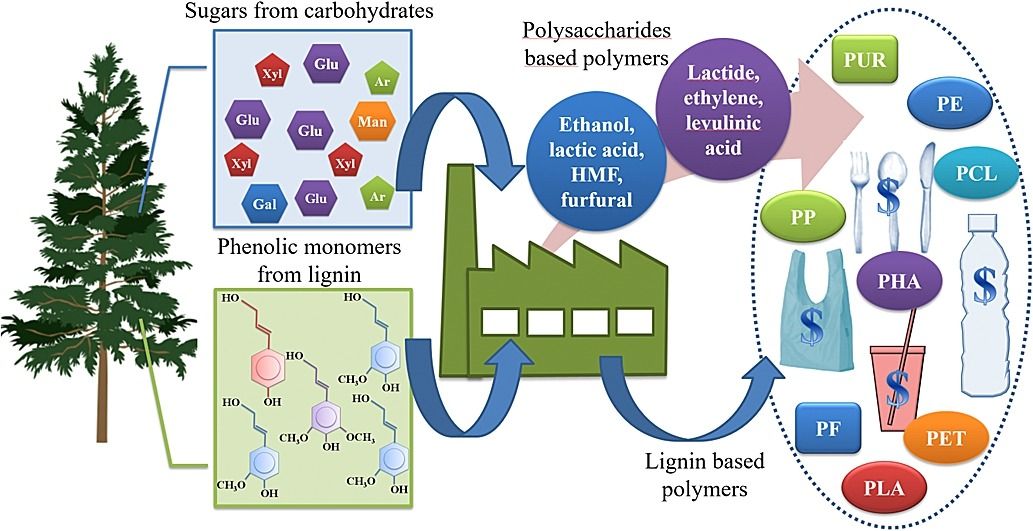

What do you mean by fiber? When we say 'fiber-based', we are talking about materials made from wood, recovered paper, and industrial production waste using scientific methods. The great thing about these materials is that they come from green sources, help save energy, and can be recycled or degraded! Among the most popular materials are ‘biocomposites', which are made of a bulk material, and fibers spread out its matrix providing strength and stiffness. The resulting material is much lighter and needs less fuel for its transport.

Wow, tell me more about these materials! Well, there is a wide range available. ‘Biocomposites' mold like plastic and offer similar strength. Natural fiber-based polymers can be used in the building industry and chemicals made of softwood can be turned into fragrances, solvents, and even biofuels! Microfibrillated cellulose (MFC) can be used as ‘barrier paper’ and film and corrugated board packaging will keep food fresh longer than plastic!.

Wait, how can that be? Well, there is scientific proof! For example, a recent study has found that compared to plastic packaging, corrugated cardboard trays significantly reduce the transfer of microbes from packaging to fruit. Peaches in a study stayed fresh longer because the cardboard could entrap microbes. A bonus that conscious consumers will surely appreciate if a corrugated box falls in the ocean, it can biodegrade in a couple of months.

OK, these are great innovations, but do customers care? Sure, they do! A UK survey in 2018. found that 64% of grocery shoppers have changed how they shop to reduce exposure to chemicals from plastic food and drink packaging. Additionally, 76% of respondents heard of plant-based packaging and 62% wanted to learn more about the topic.

And what is stopping them from a definite “yes”? Interestingly, it is poor governance and illegal logging of trees in some countries. Packaging companies want to ensure that their raw materials are sourced legally and don't want to be linked to practices that could harm their reputation. Another consumer concern is the irresponsible harvesting of natural forests that can hurt wildlife. In the case of fiber-based and building materials, customers need reassurance about safety with studies like this about how flammability is reduced. And in the case of corrugated cardboard, they want to know that proper hygiene standards are in place to prevent mold growth on food packaging.

So, what needs to be done? Consumers already look favorably at renewable materials because of their green credentials – the fact that they are biodegradable and have lower environmental impacts than traditional materials. What can further convince them is that they are sourced legally and ethically while meeting the same quality standards as the materials they are supposed to replace, and… cost – in some markets this seems to be a major obstacle. So, more financial incentives by governments could make product pricing competitive, ensuring that conscious consumers don’t feel out of pocket.

The magic of mushrooms – as a packaging solution

Although some people immediately think of a certain hallucinogenic drug, there is such a thing as fungi-based packaging!

It was invented by a popular Scandinavian home and furnishing chain. The scientists working for them discovered the material under the mushroom's outer shell – mycelia - can be mixed with other natural compounds and molded into solid packaging shapes.

Meanwhile, the stems of mushrooms can be used as a source of a protective and cushioning alternative material to environmentally harmful polystyrene that ends up in landfills and breaks down over millennia.

The wonderful advantage of fungi packaging is that it decomposes within 30-30- days. Even more exciting is that if the packaging is digested by living organisms it has no adverse side effects.

Mark has distilled 7 research papers saving 24.5 hours of reading time